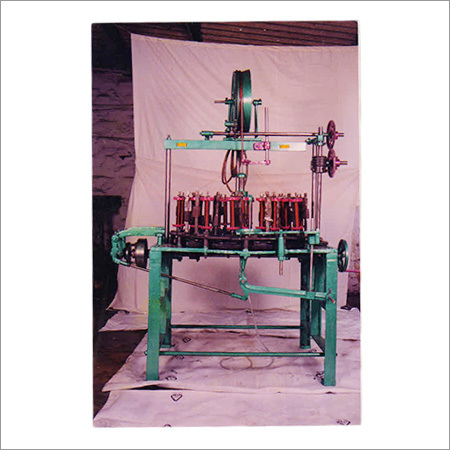

Textile Braiding Machine

Price 14000 USD ($)/ Unit

Textile Braiding Machine Specification

- Carrier

- Standard (Typically 16/24/32 as per machine design)

- Machine Speed

- Adjustable, up to 350 rpm

- Bobbin Size

- Standard (Customizable as per requirement)

- Product Type

- Textile Braiding Machine

- General Use

- Braiding yarns, cords, shoelaces, ropes, and tapes

- Material

- Mild Steel Body

- Capacity

- Depends on number of spindles (typically 8-64 spindles)

- Weight (kg)

- Approx. 450-700 kg

- Type

- Vertical Braiding Machine

- Panel

- Digital Control Panel

- Oil Bath

- Yes

- Computerized

- No

- Automatic

- Yes

- Knitting Style

- Braiding (not knitting)

- Machine Power

- 3-5 HP

- Motor Power

- 2-3 HP

- Spindle RPM

- 130-350 rpm (variable)

- Traction RPM

- 10-30 rpm

- Horn Gear Speed

- 20-30 rpm

- Needle Type

- Not Applicable (Braiding needles not used)

- Voltage

- 220V / 380V, 3 Phase

- Dimension (L*W*H)

- Approx. 1550 x 1100 x 1850 mm

- Feature

- Low noise, easy maintenance, high efficiency

- Color

- Sky Blue

- Pattern Capacity

- Standard round, flat, and tubular braid

- Drive System

- Belt and gear drive

- Lubrication System

- Centralized auto lubrication

- Production Output

- Up to 50 meters per minute

- Noise Level

- <70 dB

- Application

- Shoelaces, ropes, elastic tapes, lanyards, cords, decorative braids

- Machine Structure

- Heavy-duty, vibration-free base

- Control System

- Push Button/PLC based (optional)

- Number of Spindles

- 8 to 64 (as per model)

- Thread Range

- 0.5 mm to 8 mm

Textile Braiding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units, , Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Textile Braiding Machine

Manufacturing and supplying a wide range of items, we have emerged as best option in the market. This Textile Braiding Machine is fabricated by utilizing high quality required materials with the assistance of modern technology under the supervision of our experts. It is demanded in the market because of its highly effective and durable in nature. The provided Textile Braiding Machine is properly checked on the various quality parameters before dispatching it from our premises.

Product Details

|

Country of Origin |

Made in India |

|

Brand |

SEMCO |

|

Power Consumption |

0.75 KW |

|

Machine Type |

Automatic |

|

Motor Power |

3 Phase |

|

Speed |

370 RPM |

|

Model Name/Number |

90 Series - 32/2 |

Efficient Braiding for Multiple Applications

Engineered to serve a wide range of industries, this braiding machine crafts high-quality cords, ropes, shoelaces, elastic tapes, lanyards, and decorative braids in one seamless process. Its flexibility and capacity allow for uniform production, catering to both small and bulk requirements.

Advanced Control and Minimal Maintenance

With an intuitive digital control panel and optional PLC-based system, operators can easily manage speed and pattern settings. The centralized automatic lubrication ensures smooth operation, prolonging component life while reducing manual maintenance demands.

Built for Stability and Quiet Operation

The heavy-duty base reduces vibration, enabling precision braiding at speeds up to 350 rpm. Operating at under 70 dB, the machine ensures a comfortable working environment, especially important for continuous or large-scale manufacturing tasks.

FAQs of Textile Braiding Machine:

Q: How does the number of spindles affect the production output?

A: Production output and overall machine capacity increase with a higher number of spindles. Depending on your application, models with 8 to 64 spindles can produce varied braid widths and complexities, with maximum output up to 50 meters per minute.Q: What materials can be used in this textile braiding machine?

A: This machine is compatible with a wide range of yarns and threads (0.5 mm to 8 mm in diameter), making it ideal for producing cords, shoelaces, ropes, elastic tapes, lanyards, and other decorative braids.Q: Where is this braiding machine typically installed and used?

A: The machine is primarily used in textile manufacturing units, footwear industries, and rope-making facilities. Its robust and compact design makes it suitable for integration into established industrial production lines across India and international markets.Q: What is the process behind textile braiding in this machine?

A: The braiding process involves feeding yarns onto bobbins, which are positioned in carriers that rotate around each other via a combination of gear and belt drives. As the spindles turn, the threads intertwine into preset round, flat, or tubular braid patterns, controlled through the digital panel.Q: What are the main benefits of centralized automatic lubrication?

A: Centralized automatic lubrication ensures optimal distribution of oil across moving parts, reducing wear, prolonging the machines lifespan, and minimizing maintenance frequency. This feature contributes to smoother, uninterrupted braiding operations.Q: How does the control system work, and what options are available?

A: Operators can manage machine speed, pattern, and braiding parameters through a digital control panel. For advanced automation, an optional PLC-based system is available, allowing further customization and process optimization.Q: Is this machine easy to maintain and operate?

A: Yes, the heavy-duty structure and centralized lubrication system minimize manual intervention. The push button/digital control panels and optional PLC controls simplify operation, making the machine user-friendly and efficient for operators of various skill levels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

17 Spindle Braiding Machine

Price 5400 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel Body

Traction RPM : 120 RPM

General Use : Braiding textile yarns, threads, or wire

Carrier : 17

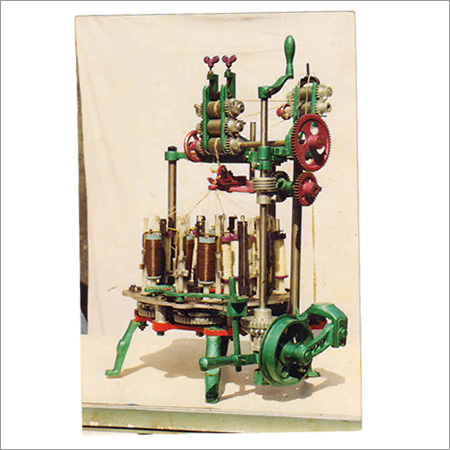

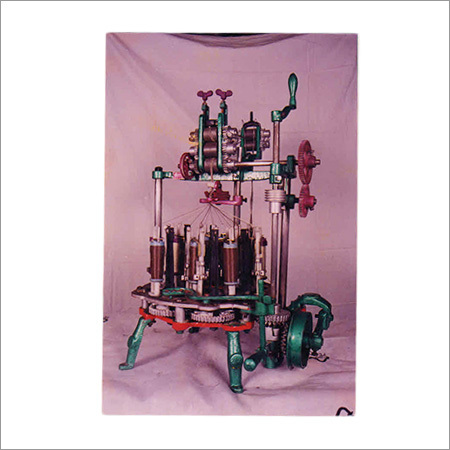

Special Braiding Machines

Price 8000-80000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Highgrade steel, cast iron

Traction RPM : 860 RPM (adjustable)

General Use : Industrial cord and rope making, specialty braided products

Carrier : 16, 24, 32, 48 (custom on request)

12 Spindle Rope Braiding Machine

Price 100.00 - 5000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Material : Other, Mild Steel Body

Traction RPM : 50200 RPM

General Use : Rope manufacturing, braiding ropes and cords

Carrier : 12

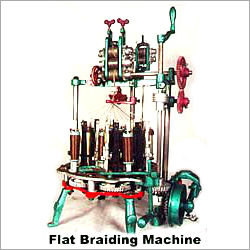

Flat Braiding Machine

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel (Frame and Parts)

Traction RPM : Up to 12 RPM

General Use : Textile Industry, Cord and Lace Making

Carrier : 16 (Standard), Available 824 as per model

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS