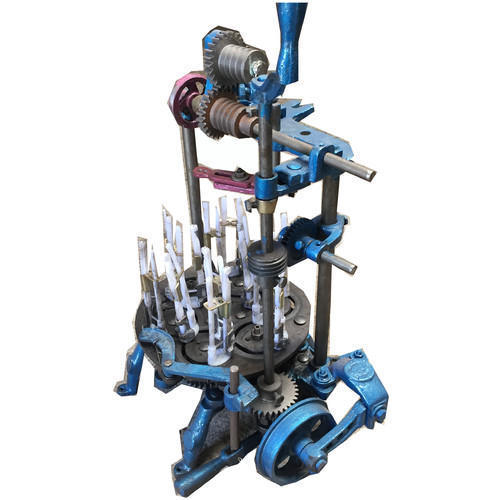

Round Conventional Braiding Machine

MOQ : 1 , , Unit

Round Conventional Braiding Machine Specification

- Machine Speed

- Max. 250 RPM

- Bobbin Size

- 75 mm x 225 mm

- Carrier

- 24/32/36/40 (As per model)

- Product Type

- Round Conventional Braiding Machine

- General Use

- For braiding round cord, ropes, laces, and similar articles

- Material

- Mild Steel (Body), Hardened Steel (Gears and Shafts)

- Capacity

- Depends on number of carriers; typically 24, 32 or more bobbins

- Weight (kg)

- Approx. 450 kg (varies by model/bobbin count)

- Type

- Conventional Mechanical

- Panel

- Control Panel with Mechanical Controls

- Oil Bath

- Provided for Main Gear Box and Bearings

- Computerized

- No

- Automatic

- Semi-Automatic

- Knitting Style

- Round Braiding

- Machine Power

- 2 HP 3 HP

- Motor Power

- 1.5 kW

- Spindle RPM

- 150 250 RPM (Adjustable)

- Traction RPM

- 25 40 RPM

- Horn Gear Speed

- Adjustable up to 250 RPM

- Needle Type

- Not Applicable (braiding process does not require sewing needles)

- Voltage

- 415V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- Approx. 1800 mm x 1200 mm x 1900 mm

- Feature

- Heavy Duty Structure, Low Noise, Smooth and Consistent Braiding

- Color

- Industrial Blue/Green with Chrome and Black Accents

- Production Output

- Up to 45 meters/hour (depends on product and model)

- Operator Requirement

- 1 Operator per Machine

- Braiding Diameter Range

- 3 mm to 25 mm (with suitable tooling)

- Compatible Material

- Cotton, PP, Nylon, Polyester, Jute, Yarn, etc.

- Safety Features

- Emergency Stop, Protective Covers

- Transport

- Base Frame with Lifting Eyelets

- Drive

- Belt Drive with Gear Reduction

- Lubrication

- Centralized Oil Bath System

- Noise Level

- Below 75 dB

- Accessories Included

- Spanner Set, Extra Bobbin Cores, Lifting Hooks

- Surface Finish

- Powder Coated/Enamel Painted

Round Conventional Braiding Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Months

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America, North America, Africa

- Main Domestic Market

- All India

About Round Conventional Braiding Machine

| SIZE OF SLEVINGS | ||

| No. of Spindles in the Machine | Size of the product in mm inner diameter | |

| 16 | 1 | |

| 20 | 1.5 | |

| 24 | 2 | |

| 32 | 2.50 to 3.00 | |

| 40 | 4 | |

| 44 | 5 | |

| 48 | 6 | |

| 56 | 7 | |

| 64 | 8 | |

| 75 | 10 | |

| 80 | 12 | |

| 100 | 15 | |

We are offering qualitative Round Conventional Braiding Machine which is utilized in assembling units for braiding procedures. It is highly durable in nature. This machine is demanded in the market for its robust structure, excellent performance and high quality. All the provided items are tested on the various quality parameters before dispatching them from our premises. Our clients can avail this Round Conventional Braiding Machine from us at a reasonable price rate within the promised time frame.

Specification

|

Capacity |

320 m/8 Hour |

|

Machine Type |

Semi-Automatic |

|

Power Consumption |

1 hp |

|

Brand |

Semco |

|

Material |

MS, Aluminum Body |

|

Country of Origin |

Made in India |

|

Number of Spindles |

56 |

|

Product Inner Diameter |

7 mm |

Versatile Braiding Performance

This machine accommodates a wide range of materials, such as cotton, polyester, nylon, jute, and yarn, delivering a consistent round braiding style. Its adjustable diameter and carrier configuration allow for flexible production according to specific requirements for cords, ropes, or laces. The powerful motor and smooth gear system guarantee efficient output for demanding manufacturing environments.

Safety and Reliability

Equipped with emergency stop mechanisms and protective covers, the machine prioritizes operator safety at every stage of the process. Its centralized oil bath lubrication preserves internal components, optimizing longevity and performance. Low noise levels below 75 dB ensure a comfortable workspace, enhancing daily operations without compromising speed or quality.

User-Friendly Operation

Featuring easy-to-use mechanical controls and requiring just one operator per machine, this braiding solution streamlines workflow. Accessories like spanner sets, extra bobbin cores, and lifting hooks are supplied for hassle-free maintenance. The base frame with lifting eyelets facilitates transport, making it suitable for diverse production facilities.

FAQs of Round Conventional Braiding Machine:

Q: How does the Round Conventional Braiding Machine operate and what materials can it process?

A: The machine uses a belt drive with gear reduction for smooth mechanical braiding of round cords, ropes, and laces. It is compatible with a variety of materials, including cotton, polypropylene (PP), nylon, polyester, jute, and yarn.Q: What are the safety features included with this braiding machine?

A: Safety is ensured through emergency stop controls, protective covers over moving parts, and a robust heavy-duty frame. These features mitigate risks during operation and protect operators from potential hazards.Q: When is centralized oil bath lubrication required and how does it benefit the machine?

A: Centralized oil bath lubrication is active during machine operation, continuously servicing the main gearbox and bearings. This reduces wear, maintains smooth functioning, and extends the lifespan of mechanical components.Q: Where can this braiding machine be installed and transported easily?

A: Thanks to its base frame with lifting eyelets, the machine can be installed in various industrial environments and moved when necessary. Its durable construction allows for straightforward transport and placement in factories or workshops.Q: What is the typical process and production output for this machine?

A: The machine follows a conventional round braiding process, with adjustable spindle and horn gear RPM. Depending on the product and model, it can produce up to 45 meters per hour, making it suitable for batch and continuous manufacturing.Q: How many operators are needed for efficient machine usage?

A: Only one operator is required to manage each machine, thanks to its straightforward mechanical control panel and semi-automatic functions. This streamlines production and reduces labor costs.Q: What are the main benefits of using this braiding machine for manufacturing?

A: This machine offers heavy-duty performance, low noise operation, excellent surface finishing (powder-coated or enamel painted), and reliable output across various materials. Its accessories and safety attributes make it both practical and safe for industrial use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free