Braiding Machine Spindles

Price 2000 INR/ Piece

Braiding Machine Spindles Specification

- Carrier

- Lightweight, corrosion resistant

- Bobbin Size

- Standard 42 mm to 95 mm

- Product Type

- Braiding Machine Spindles

- General Use

- Textile Braiding Machinery

- Material

- High Grade Alloy Steel

- Type

- Braiding; Wire and Yarn Compatible

- Computerized

- No

- Automatic

- No

- Traction RPM

- Adjustable as per requirement

- Feature

- Low Noise, High Precision, Durable

- Color

- Metallic / Customized

- Packing Type

- Carton/Box or Wooden Case as required

- Outer Diameter

- 30 mm to 55 mm

- Compatibility

- Fits most standard braiding machines

- Service Life

- Long Operational Life

- Inner Diameter

- 12 mm to 20 mm (customizable)

- Balancing

- Dynamically Balanced

- Surface Treatment

- Polished and Anti-corrosive Coating

- Noise Level

- <70 dB

- Application Area

- Textile, Rope, Cable, Shoe Lace, and Packing Industries

- Maintenance

- Low, Easy to Assemble/Disassemble

- Hardness

- 45-55 HRC

Braiding Machine Spindles Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Braiding Machine Spindles

Braiding Machine Spindles offered by our company, are manufactured and supplied by our skilled workers by making use of premium grade of raw materials and upgraded techniques. These spindles are used to braid high tensile steel wires on the hose pipes. These spindles are highly durable and do not easily bend. Braiding Machine Spindles are designed to deliver high performance and long functional service life. These spindles are very effective as well as economical to use. These spindles deliver high performance, corrosion resistant finish and high process reliability support.

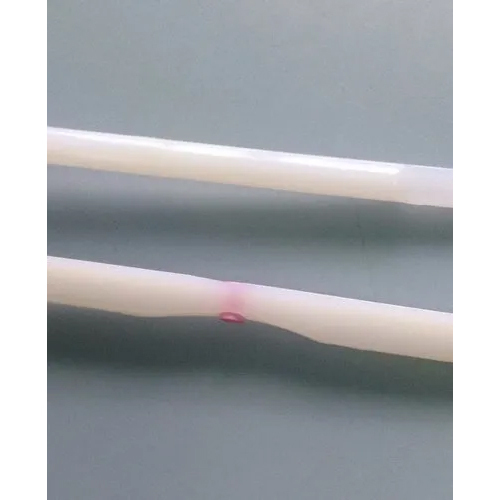

Specification

|

Material |

Nylon |

|

Automation Grade |

Manual |

|

Diameter |

40 mm |

|

Brand |

Semco |

|

Surface Finish |

Polished |

|

Packaging |

Packet |

|

Color |

White |

Engineered for Versatility and Performance

Designed for compatibility with most standard braiding machines, these spindles cover a spectrum of applications-textiles, ropes, cables, shoelaces, and packaging. Their high-grade alloy steel construction, customizable sizes, and enhanced surface protection ensure adaptability and longevity in demanding operational environments.

Precision Balanced for Smooth Operation

Visibly reduced vibration and noise thanks to dynamic balancing and a robust structure. The spindle's low noise level, under 70 dB, combined with adjustable machine speed (up to 2500 RPM), boosts both operator comfort and manufacturing output quality.

Durability Meets Ease of Maintenance

A polished finish and anti-corrosive coating provide resistance to wear and harsh conditions, ensuring a prolonged service life. The low-maintenance design makes assembly and disassembly straightforward, supporting efficient replacements and servicing with minimal downtime.

FAQ's of Braiding Machine Spindles:

Q: How do I install or replace a spindle on my braiding machine?

A: The spindle is engineered for easy installation and removal. Simply disengage the securing mechanism of your braiding machine, slide out the old spindle, and insert the new one. Detailed guidelines are provided with each shipment, and no specialized tools are required.Q: What applications are these spindles suitable for?

A: These spindles are versatile, making them suitable for textiles, rope, cable manufacturing, shoelace production, and other packing industries. Their robust construction and high-precision design support a variety of wire and yarn types.Q: When should I perform maintenance on the spindle?

A: Routine maintenance is minimal due to the high-quality materials and protective coatings. It's recommended to inspect the spindles during regular machine service intervals to check for signs of wear or build-up. Lubrication can be applied if the oil bath option is chosen.Q: Where are these spindles manufactured and shipped from?

A: All spindles are manufactured, exported, and supplied from our facility in India. Packaging options include standard carton/box or wooden case, tailored to your shipping and storage requirements.Q: What are the main benefits of using these braiding machine spindles?

A: Users benefit from high precision, low noise, and long operational life. The anti-corrosive coating, dynamic balancing, and customizable sizing contribute to superior performance and reduced maintenance costs.Q: How does the dynamic balancing feature improve machine operation?

A: Dynamic balancing minimizes vibration, ensuring smoother machine operation at high speeds (up to 2500 RPM). This leads to quieter functioning, less wear on machine components, and improved product consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free