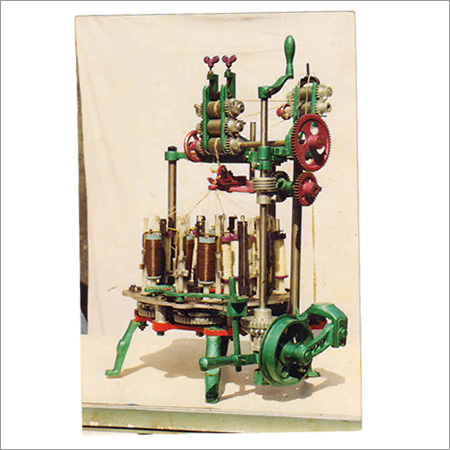

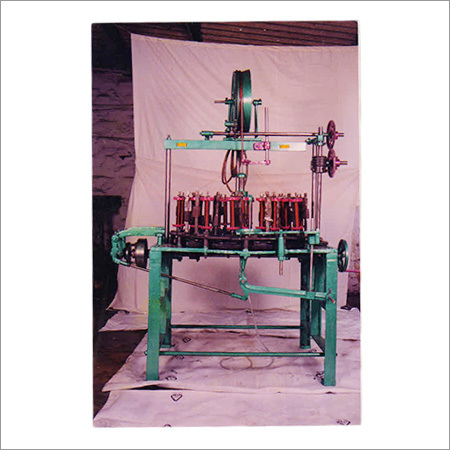

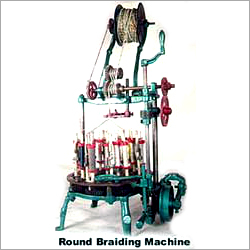

Special Braiding Machines

Price 8000-80000 INR/ Unit

Special Braiding Machines Specification

- Machine Speed

- Up to 320 RPM

- Carrier

- 16, 24, 32, 48 (custom on request)

- Bobbin Size

- Standard: 48 mm; other sizes on request

- Product Type

- Special Braiding Machines

- General Use

- Industrial cord and rope making, specialty braided products

- Material

- High-grade steel, cast iron

- Capacity

- Varies by model (custom variants available)

- Weight (kg)

- Approx. 400-850 kg (varies by configuration)

- Type

- Heavy-duty automatic braiding machine

- Panel

- Digital control panel

- Oil Bath

- Yes

- Computerized

- No

- Automatic

- Yes

- Knitting Style

- Braided (multiple patterns)

- Machine Power

- 2 HP to 5 HP

- Motor Power

- 1.5 kW 3.7 kW

- Spindle RPM

- 200-350 RPM

- Traction RPM

- 8-60 RPM (adjustable)

- Horn Gear Speed

- 240 RPM 320 RPM

- Needle Type

- Not Applicable (uses bobbins/carriers)

- Voltage

- 380V/415V, 3 Phase 50/60 Hz

- Dimension (L*W*H)

- Approx. 2200 x 1250 x 1800 mm

- Feature

- High speed, low noise, uniform tightness, sturdy design

- Color

- Green/Blue or as per order

- Service Support

- On-site Installation & Training

- Main Shaft Material

- Alloy Steel, Hardened & Ground

- Max Braid Diameter

- 3 mm to 20 mm (depending on model)

- Safety Features

- Emergency Stop, Overload Protection

- Braiding Pitch Adjustment

- Variable

- Control System

- PLC/Manual Options

- Compliance

- CE Certified (on request)

- Optional Accessories

- Creel Stand, Take Up Device, Tension Controller

- Noise Level

- < 80 dB

- Application

- Shoelaces, Ropes, Flat/round Braids, Cords, Harness Cables

- Operating Temperature

- Up to 45°C

- Drive Type

- Belt or Gear Drive

- Power Consumption

- Approx. 2-5 kWh

- Lubrication

- Centralized/Automatic Lubrication

Special Braiding Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units, , Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Special Braiding Machines

Your search for top-grade Special Braiding Machines ends here. We are a trusted entity in this space which is involved in the process of manufacturing and supplying premium quality range of items to our consumers. This item is made by utilizing great quality required materials with the help of sophisticated technology under the supervision of our experts. It is demanded in the market because of its high quality and durability. We offer this Special Braiding Machines at market leading price rate.

Specification

|

Automation Grade |

Semi-Automatic |

|

Capacity |

105 m/8 hours |

|

Material |

MS Body |

|

Brand |

Samco |

|

Surface Treatment |

Powder Coated |

|

Usage/Application |

Textile Industry |

|

Country of Origin |

Made in India |

Versatile Control Options

Choose between user-friendly PLC controls or manual operation to suit your production environment. The digital control panel allows precise adjustments for braid pitch and speed, supporting a wide range of braiding styles and material types.

Durable and Reliable Design

Built with high-grade steel and cast iron, these machines feature a hardened and ground alloy steel main shaft, ensuring a long operational life and stable performance, even in continuous heavy-duty use.

Efficient and Safe Operation

Automatic lubrication, emergency stop, and overload protection offer peace of mind for operators while maintaining the machines performance and minimizing maintenance needs. Each model supports easy maintenance and optimal uptime.

FAQs of Special Braiding Machines:

Q: How does the braiding machine accommodate different product types such as shoelaces, ropes, and cables?

A: The machine features adjustable braiding pitch, changeable carriers, and supports a range of bobbin sizes, making it suitable for a variety of products like shoelaces, flat and round ropes, harness cables, and specialty braided cords.Q: What are the control system options available and how do they benefit the operator?

A: You can choose a fully programmable PLC system for precise, automated adjustments or a straightforward manual setup. This flexibility allows operators to easily tailor the machines operation to specific production needs and skill levels.Q: When is centralized or automatic lubrication used, and what advantages does it provide?

A: Centralized or automatic lubrication is used during continuous, high-speed operation and ensures consistent oiling of critical parts. This reduces wear, prolongs machine life, and lowers maintenance demands.Q: Where is the machine typically installed and what onsite support is provided?

A: The machine is ideal for industrial cord, rope, and specialty product manufacturing setups. We offer on-site installation and training to ensure smooth integration and optimal operation in your facility.Q: What is the process for adjusting the braiding pitch and braid diameter?

A: Operators can use the control panel to set the desired pitch, while exchanging bobbins or carriers allows for quick changes in braid diameteraccommodating sizes from 3 mm to 20 mm depending on the model.Q: How does the machine ensure safety during operation?

A: Safety is managed by emergency stop buttons, overload protection systems, and a sound-dampening design, all working to minimize risks and maintain a safe, quiet working environment.Q: What benefits does the machine provide in terms of productivity and reliability?

A: With high-speed operation, automatic features, and sturdy construction, the machine delivers consistently tight, uniform braids with minimal downtime or maintenanceboosting productivity and ensuring high-quality output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

17 Spindle Braiding Machine

Price 5400 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Braiding textile yarns, threads, or wire

Carrier : 17

Bobbin Size : 120 mm x 36 mm

Type : Other, Automatic Braiding Machine

Textile Braiding Machine

Price 14000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

General Use : Braiding yarns, cords, shoelaces, ropes, and tapes

Carrier : Standard (Typically 16/24/32 as per machine design)

Bobbin Size : Standard (Customizable as per requirement)

Type : Other, Vertical Braiding Machine

3 Ply Twisting Machine

Minimum Order Quantity : 1 Unit

General Use : Twisting of yarns for rope, thread, or cord manufacturing

Carrier : 3 or 6 (based on model)

Bobbin Size : 8 x 9 (Standard)

Type : Other, Twisting Machine

Round Type Rope Braiding Machine

Minimum Order Quantity : 1 Unit

General Use : Used for braiding ropes, cords, and laces in various industries

Carrier : 6, 8, 12, 16, 24 (various models available)

Bobbin Size : Standard 45mm x 115mm / 50mm x 140mm (varies by configuration)

Type : Other, Automatic Braiding Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free