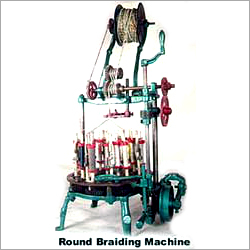

Round Type Rope Braiding Machine

Round Type Rope Braiding Machine Specification

- Machine Speed

- 10-20 meters per minute mm/s

- Carrier

- 6, 8, 12, 16, 24 (various models available)

- Bobbin Size

- Standard 45mm x 115mm / 50mm x 140mm (varies by configuration)

- Product Type

- Round Type Rope Braiding Machine

- General Use

- Used for braiding ropes, cords, and laces in various industries

- Material

- Heavy duty steel frame with aluminum/brass components

- Capacity

- Depends on number of carriers and rope size; typically up to 10-20 meters/minute m3/hr

- Weight (kg)

- Approx. 350-420 kg (varies by model) Tonne

- Type

- Automatic Braiding Machine

- Computerized

- No

- Machine Power

- 2.2 kW Megawatt (MW)

- Motor Power

- 1.5 HP (approx) Horsepower (HP)

- Spindle RPM

- 80-160 RPM (adjustable) mm/m

- Traction RPM

- Up to 50 RPM

- Horn Gear Speed

- Variable, up to 60 cycles/minute sq m/hr

- Voltage

- 220V / 380V, 50/60Hz Ampere (amp)

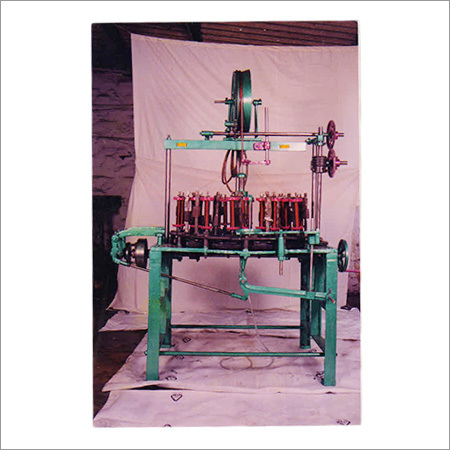

- Dimension (L*W*H)

- Approx. 1800 mm x 1200 mm x 1750 mm Millimeter (mm)

- Feature

- Low noise, durable, high efficiency

- Color

- Blue & Silver (as per image)

- Usage/Application

- Textile, Marine, Agriculture, Sporting Goods, Packaging

- Installation

- Floor mounted, adjustable legs for leveling

- Braiding Diameter Range

- 2 mm to 16 mm (depending on model and settings)

- Power Supply

- Three phase/single phase optional

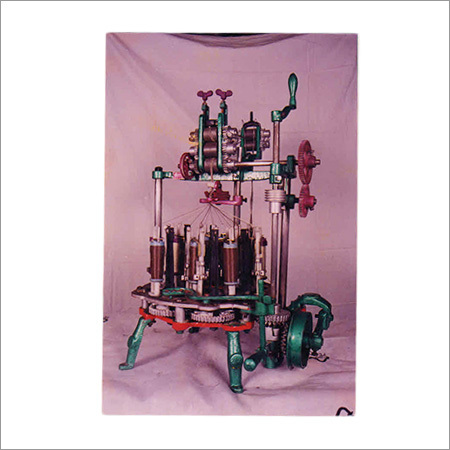

- Lubrication

- Centralized automatic grease lubrication

- Control System

- Start/Stop button with emergency off switch

- Spindle Type

- Heavy duty, balanced type for vibration-free running

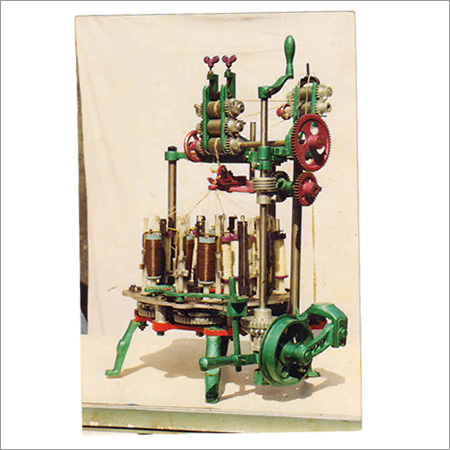

- Drive System

- Belt and gear driven mechanism for smooth operation

- Noise Level

- Below 65 dB

- Finish

- Powder coated corrosion-resistant body

- Productivity

- Continuous operation for extended production batches

- Safety Features

- Safety covers and emergency shut-off switches

Round Type Rope Braiding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units, , Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Round Type Rope Braiding Machine

Round Type Rope Braiding Machine

By going through the processing of manufacturing and supplying qualitative range of Round Type Rope Braiding Machine to our client that is made by using high quality required materials with the help of sophisticated technology. This item is utilized for the braiding procedures. It holds the features like robust structure, hassle free functioning and superb durability. Offered Round Type Rope Braiding Machine is supplied by us at a reasonable price rate within the promised time frame.

Advanced Drive and Control Systems

The braiding machine incorporates a reliable belt and gear drive system, ensuring smooth and optimal performance for extended manufacturing sessions. Operators benefit from an easy-to-use electric control panel featuring a start/stop button and an emergency off switch to promote operational safety.

Versatile Application and Capacity

Engineered for a range of industries including textiles, marine, agriculture, and sporting goods, this machine accommodates a braiding diameter from 2 mm to 16 mm. The high-capacity, heavy-duty frame supports continuous production, with output rates up to 20 meters per minute and model-specific carrier variations.

Durability and Safety Prioritized

Manufactured with a corrosion-resistant, powder-coated steel body and automatic centralized lubrication, the machine ensures long-term reliability and minimal maintenance. Safety elements like emergency shut-off switches and full safety covers provide additional operational reassurance during high-speed runs.

FAQs of Round Type Rope Braiding Machine:

Q: How does the rope braiding machine operate and what are its control features?

A: The machine runs on a belt and gear-driven mechanism for smooth operation and is controlled via an electric panel equipped with start/stop buttons and an emergency off switch, ensuring both convenience and safety.Q: What types of ropes and cords can be produced with this machine?

A: It is capable of manufacturing round (spiral) braided ropes, cords, and laces, with diameters ranging from 2 mm to 16 mm, depending on the specific model and settings used.Q: When should centralized automatic lubrication be performed?

A: The machine features a centralized automatic grease lubrication system that continuously maintains optimal lubrication for critical moving parts during operation, removing the need for manual intervention.Q: Where can this braiding machine be installed and what are its requirements?

A: Designed for floor mounting, the machine includes adjustable legs for precise leveling and requires a stable surface with access to either single-phase or three-phase power (220V/380V, 50/60Hz).Q: What is the process for adjusting the machine for different rope sizes?

A: Changing the braiding diameter or rope size involves selecting the proper carrier and bobbin settings and adjusting the machine controls. The braiding diameter can be varied between 2 mm and 16 mm based on these parameters.Q: What are the main benefits of using this automatic braiding machine?

A: Key advantages include low-noise operation (below 65 dB), high efficiency, low maintenance due to automatic lubrication, durable build, enhanced safety features, and the ability to produce high-quality braided products continuously for large-scale output.Q: How does the machine ensure safe and reliable long-term operation?

A: Safety is reinforced with emergency shut-off switches and safety covers, while the heavy-duty construction and fully covered oil bath system ensure durability and consistent, vibration-free performance with minimal maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

17 Spindle Braiding Machine

Price 5400 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Performance, Robust Construction

General Use : Braiding textile yarns, threads, or wire

Color : Blue & White

Traction RPM : 120 RPM

Textile Braiding Machine

Price 14000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Low noise, easy maintenance, high efficiency

General Use : Braiding yarns, cords, shoelaces, ropes, and tapes

Color : Sky Blue

Traction RPM : 1030 rpm

12 Spindle Rope Braiding Machine

Price 100.00 - 5000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Feature : Other, Heavy Duty, Low Maintenance

General Use : Rope manufacturing, braiding ropes and cords

Color : Blue and White

Traction RPM : 50200 RPM

3 Ply Twisting Machine

Minimum Order Quantity : 1 Unit

Feature : Other, Low noise, Highefficiency

General Use : Twisting of yarns for rope, thread, or cord manufacturing

Color : Blue, White, or Custom

Traction RPM : 1100 rpm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free