3 Ply Twisting Machine

3 Ply Twisting Machine Specification

- Bobbin Size

- 8 x 9 (Standard)

- Machine Speed

- Adjustable, up to 9000 rpm m/s

- Carrier

- 3 or 6 (based on model)

- Product Type

- 3 Ply Twisting Machine

- General Use

- Twisting of yarns for rope, thread, or cord manufacturing

- Material

- Mild Steel Frame, Alloy Steel Components

- Capacity

- Up to 150 kg/day Ltr

- Weight (kg)

- Approx. 1000 kg Metric Ton

- Type

- Twisting Machine

- Oil Bath

- Yes

- Computerized

- No

- Machine Power

- 5 HP Watt (W)

- Motor Power

- 3.7 kW Volt (V)

- Spindle RPM

- Up to 9000 rpm RPM

- Traction RPM

- 1100 rpm

- Horn Gear Speed

- 200 to 800 rpm mm/m

- Voltage

- 220V / 380V / 415V (3 phase) Megaampere ( MA)

- Dimension (L*W*H)

- 4500 x 1300 x 1900 mm Yard

- Feature

- Low noise, High-efficiency

- Color

- Blue, White, or Custom

- Frame Structure

- Heavy Duty Welded Construction

- Electrical Protection

- Overload & Short circuit protection

- Tension Device

- Electromagnetic

- Power Consumption

- Approx. 4-5 kWh

- Twist Range

- 60-400 TPI (Twist Per Inch)

- Creel Capacity

- 6 ends / 9 ends options

- Spindle Gauge

- 200 mm

- Application

- PP/HDPE/Raffia/Polyester/Nylon Yarn Twisting

- Lubrication System

- Centralized Oil Bath

- Control System

- PLC Based (Optional)

- Noise Level

- < 80 dB

- Drive Type

- Belt & Pulley Drive

3 Ply Twisting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About 3 Ply Twisting Machine

3 Ply Twisting Machine

Backed by our rich industry experience, we are engaged in offering 3 Ply Twisting Machine to our valuable clients. The range of this machine is made by utilizing high quality required materials with the assistance of innovative technology. It is demanded in the market because of its hassle free functioning, robust structure, high quality and durability. This machine is utilized in the industries for twisting procedures. Our clients can avail this 3 Ply Twisting Machine from us at market leading price rate.

Specification

|

Usage/Application |

Yarn Twisting |

|

Material |

MS Body |

|

Capacity |

250 m/8 hours |

|

Power Consumption |

1 hp |

|

Brand |

Samco |

|

Machine Type |

Manual |

|

Country of Origin |

Made in India |

Robust Frame and High Capacity

Built with heavy-duty welded mild steel and alloy steel components, this twisting machine endures continuous industrial use. Its capacity reaches up to 150 kg per day, ensuring productivity remains high for manufacturers seeking output reliability and strength.

Advanced Control and Safety Features

Operators can opt for PLC-based control systems and digital or analog panels to enhance ease of use. Electrical protection encompasses overload and short circuit safeguarding, while adjustable machine speed and an oil bath lubrication system deliver optimal efficiency and long equipment life.

Versatility for Multiple Yarn Types

Designed for applications such as rope, thread, and cord manufacturing, the machine can twist a variety of synthetic yarns including PP, HDPE, Raffia, Polyester, and Nylon. Its adjustable spindle and tension devices cater to differing yarn requirements, supporting adaptability in production lines.

FAQs of 3 Ply Twisting Machine:

Q: How does the 3 Ply Twisting Machine ensure consistent yarn quality?

A: The machine uses an electromagnetic tension device and precise belt & pulley drive to maintain consistent twist across all yarns. Combined with a centralized oil bath lubrication system, it minimizes friction-related irregularities and guarantees high-quality twisted yarn output every cycle.Q: What types of yarn can be processed with this twisting machine?

A: This machine is suitable for a wide range of synthetic yarns, specifically PP, HDPE, Raffia, Polyester, and Nylon. It is primarily used for making ropes, threads, and cords, offering flexibility for numerous industrial and commercial textile applications.Q: When is centralized oil bath lubrication beneficial in operation?

A: Centralized oil bath lubrication is especially beneficial during continuous, high-speed operation. It reduces wear on gears and essential components, diminishing maintenance frequency and extending the machines operational life while ensuring quieter, smoother performance.Q: Where can this machine be installed and operated effectively?

A: Ideal for textile manufacturing facilities, rope and cord production plants, or any industrial environment requiring efficient yarn twisting. Its sturdy construction and moderate noise levels (below 80 dB) make it suitable for both large-scale and mid-sized manufacturing units.Q: What are the main benefits of the PLC-based control system?

A: The optional PLC-based control system offers enhanced automation, simplified operation, and precise parameter adjustments. This helps reduce human error, facilitate quick changeovers, and support efficient monitoring, which together increase overall productivity and product consistency.Q: How does the machine handle electrical safety?

A: The equipment is safeguarded with both overload and short circuit protection features. This ensures continued safe operation in fluctuating power environments, protecting both the machinery and the operational staff.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

Special Braiding Machines

Price 8000-80000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Approx. 2200 x 1250 x 1800 mm

Motor Power : 1.5 kW 3.7 kW

Voltage : 380V/415V, 3 Phase 50/60 Hz

Color : Green/Blue or as per order

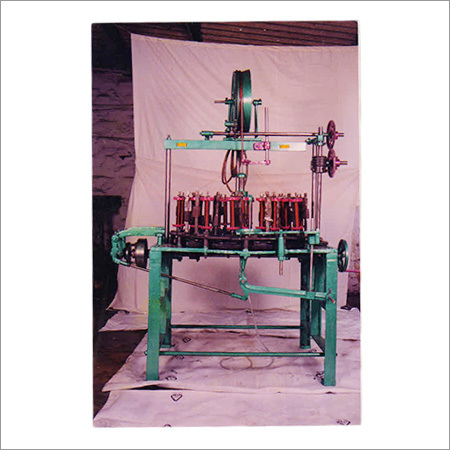

12 Spindle Rope Braiding Machine

Price 100.00 - 5000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Dimension (L*W*H) : 1850 x 1220 x 1600 mm

Motor Power : 2.2 kW

Voltage : 380 V

Color : Blue and White

Textile Braiding Machine

Price 14000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Approx. 1550 x 1100 x 1850 mm

Motor Power : 23 HP

Voltage : 220V / 380V, 3 Phase

Color : Sky Blue

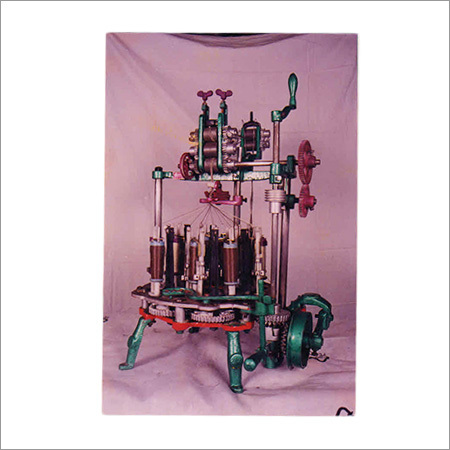

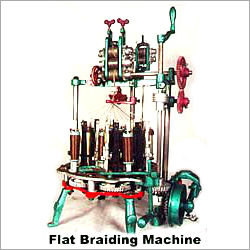

Flat Braiding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 2300 mm x 800 mm x 1700 mm

Motor Power : 1.5 HP (Heavy Duty Motor)

Voltage : 220240 V, 50/60 Hz

Color : Industrial Blue & Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free