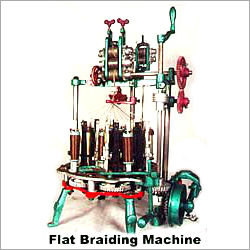

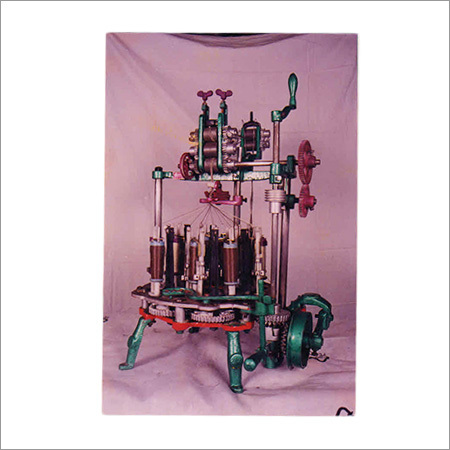

Flat Braiding Machine

Flat Braiding Machine Specification

- Machine Speed

- Up to 320 Spindle RPM

- Bobbin Size

- 48 mm x 140 mm

- Carrier

- 16 (Standard), Available 8-24 as per model

- Product Type

- Flat Braiding Machine

- General Use

- Textile Industry, Cord and Lace Making

- Material

- Mild Steel (Frame and Parts)

- Capacity

- Continuous Operation with High Output (Up to 50 m/h, varies by yarn type)

- Weight (kg)

- Approx. 450 kg

- Type

- Automatic Braiding Machine

- Panel

- Digital Control Panel

- Oil Bath

- Yes

- Computerized

- No

- Automatic

- Yes

- Knitting Style

- Flat Braided Structure

- Machine Power

- 1.5 HP

- Motor Power

- 1.5 HP (Heavy Duty Motor)

- Spindle RPM

- Up to 320 RPM

- Traction RPM

- Up to 12 RPM

- Horn Gear Speed

- 320 RPM

- Needle Type

- Braiding Needle

- Voltage

- 220-240 V, 50/60 Hz

- Dimension (L*W*H)

- 2300 mm x 800 mm x 1700 mm

- Feature

- Low Noise, Smooth Operation, Compact Design

- Color

- Industrial Blue & Silver

- Output Width

- Up to 100 mm (depends on yarn and setup)

- Number of Spindles

- 16 (customizable up to 24 depending on model)

- Lubrication System

- Automatic Oil Bath

- Application

- Shoelace, Flat Cords, Laces, Elastic, Decorative Trims, Medical Tapes

- Control System

- PLC or Digital Push Button Panel

- Suitable Yarn Types

- Cotton, Polyester, Nylon, Rayon, Polypropylene, etc.

- Noise Level

- Below 75 dB(A)

- Drive System

- Belt Driven with Safety Covers

- Production Speed

- 30~50 m/h (varies with yarn and braiding pattern)

- Installation

- Floor Mounted

- Finish

- Powder Coated Frame for Rust Resistance

Flat Braiding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units, , Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Africa, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Flat Braiding Machine

Due to its uses and market review, we are assembling and supplying qualitative Flat Braiding Machine to our valuable clients which is made by utilizing high quality required materials with the help of modern technology. This machine has applications in the manufacturing procedures. It is high in quality and durability. All the provided items are properly checked on the various quality parameters before dispatching them from our premises. The supply of this Flat Braiding Machine is done by us at a reasonable price rate.

Specification

|

Capacity |

8 m/hour |

|

Machine Type |

Semi-Automatic |

|

Brand |

Semco |

|

Material |

Mild Steel |

|

Surface Finish |

Color Coated |

|

Usage/Application |

Rope Branding |

|

Country of Origin |

Made in India |

|

Number of Spindles |

10 |

Advanced Flat Braiding Technology

Engineered for superior braiding with an automatic oil bath system, this machine delivers consistent output at speeds of up to 50 meters per hour. With PLC or digital control options, adjustments are simple, ensuring high productivity with minimal downtime. The smooth, low-noise operation creates a comfortable and safe workspace, ideal for industrial-scale textile production.

Versatility in Yarn and Application

Whether producing shoelaces, decorative trims, or medical tapes, the machine supports cotton, polyester, nylon, rayon, and polypropylene yarns. Various output widths and customizable spindles (from 8 to 24) allow users to tailor production to specific requirements, accommodating a wide range of flat braided structures for diverse industry applications.

FAQs of Flat Braiding Machine:

Q: How does the automatic oil bath lubrication system enhance machine performance?

A: The automatic oil bath system ensures that all moving parts are continuously lubricated, reducing wear and tear and allowing for smooth, low-noise operation. This not only extends the machines lifespan but also maintains consistent quality and output speed during continuous operation.Q: What types of yarns can be used with this flat braiding machine?

A: This machine accommodates a variety of yarn types, including cotton, polyester, nylon, rayon, and polypropylene, making it suitable for producing different styles and strengths of flat braids to meet various industrial needs.Q: When is it advisable to choose a machine with a higher number of spindles?

A: A higher spindle count (up to 24, depending on the model) is recommended when increased width, production capacity, or intricate braiding patterns are required. This flexibility enables manufacturers to match machine specifications with specific project or client requirements.Q: Where is the ideal installation location for this braiding machine?

A: The machine is floor-mounted and best suited for textile production facilities, manufacturing units, or workshops with adequate space to accommodate its dimensions (2300 mm x 800 mm x 1700 mm) and provide good ventilation for heavy-duty operations.Q: What benefits does the digital control panel offer during operation?

A: The digital push button panel (or PLC control system) simplifies operation, allowing quick adjustments to production speed, braiding pattern, and monitoring of machine status. This contributes to reduced downtime, enhanced safety, and greater control over product quality.Q: How is the flat braiding process carried out on this machine?

A: Yarns are loaded onto spindles, after which the machine interlaces them through a synchronized flat braiding system, powered by a belt-driven mechanism with enclosed safety covers. The process is overseen via the digital control panel, enabling continuous, precise production of flat braided cords or laces.Q: What advantages does this machine provide for manufacturers and exporters?

A: Manufacturers and exporters benefit from its high output capacity, adaptability to various yarn materials, energy-efficient operation (1.5 HP motor), and durable, rust-resistant construction. Its low noise level and smooth operation contribute to a more efficient and safe workplace, increasing overall productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

Special Braiding Machines

Price 8000-80000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial cord and rope making, specialty braided products

Product Type : Special Braiding Machines

Bobbin Size : Standard: 48 mm; other sizes on request

Traction RPM : 860 RPM (adjustable)

12 Spindle Rope Braiding Machine

Price 100.00 - 5000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

General Use : Rope manufacturing, braiding ropes and cords

Product Type : 12 Spindle Rope Braiding Machine

Bobbin Size : Standard (20 mm x 70 mm)

Traction RPM : 50200 RPM

3 Ply Twisting Machine

Price 15000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Twisting of yarns for rope, thread, or cord manufacturing

Product Type : 3 Ply Twisting Machine

Bobbin Size : 8 x 9 (Standard)

Traction RPM : 1100 rpm

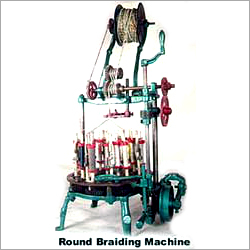

Round Type Rope Braiding Machine

Minimum Order Quantity : 1 Unit

General Use : Used for braiding ropes, cords, and laces in various industries

Product Type : Round Type Rope Braiding Machine

Bobbin Size : Standard 45mm x 115mm / 50mm x 140mm (varies by configuration)

Traction RPM : Up to 50 RPM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS