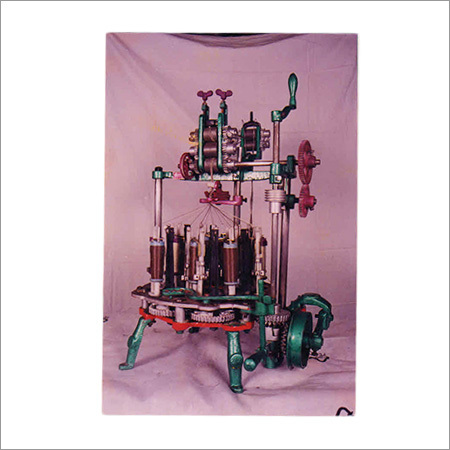

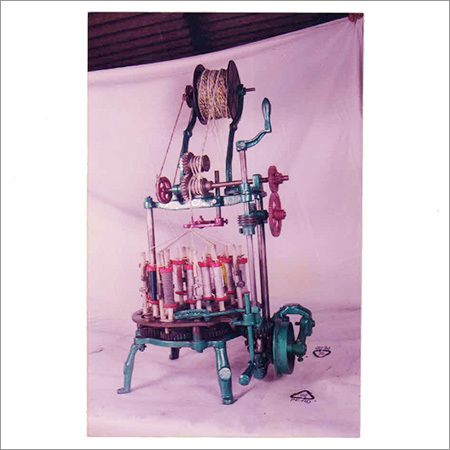

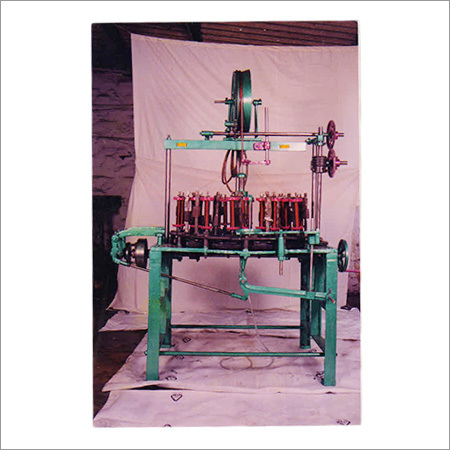

12 Spindle Rope Braiding Machine

Price 100.00 - 5000.00 USD ($)/ Unit

12 Spindle Rope Braiding Machine Specification

- Bobbin Size

- Standard (20 mm x 70 mm)

- Machine Speed

- Adjustable

- Carrier

- 12

- Product Type

- 12 Spindle Rope Braiding Machine

- General Use

- Rope manufacturing, braiding ropes and cords

- Material

- Mild Steel Body

- Capacity

- Up to 50 Meters/Hour

- Weight (kg)

- Approx. 400 kg

- Type

- Semi-Automatic

- Panel

- Control Panel Provided

- Oil Bath

- Available

- Computerized

- No

- Automatic

- No

- Knitting Style

- Braiding

- Machine Power

- 3 HP

- Motor Power

- 2.2 kW

- Spindle RPM

- 800-1200 RPM

- Traction RPM

- 50-200 RPM

- Horn Gear Speed

- Adjustable (40-120 RPM)

- Needle Type

- Braiding Needles

- Voltage

- 380 V

- Dimension (L*W*H)

- 1850 x 1220 x 1600 mm

- Feature

- Heavy Duty, Low Maintenance

- Color

- Blue and White

12 Spindle Rope Braiding Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America, Africa

- Main Domestic Market

- All India

About 12 Spindle Rope Braiding Machine

Leveraging on the expertise of our dexterous personnel, we are involvedin supplying a premium quality 12 Spindle Rope Braiding Machine to our valuable patrons that is made by utilizing high quality required materials with the help of innovative technology. This item is utilized in the machinery applications for braiding or twisting. It is demanded in the marker because of its high quality and durability. We supply this 12 Spindle Rope Braiding Machine at market leading prices within stipulated time period.

Product Details

|

Usage/Application |

Textile,Fishing,Sports,Garments,Footwear etc |

|

Brand |

SEMCO |

|

Capacity |

200- 250mtr (Approx 8hrs) |

|

Machine Type |

Manual |

|

Motor Power |

1 HP Motor 10 MAchines |

|

Model Name/Number |

12 Spindle Machine. |

|

Grade |

Pure Casting. |

|

Production Capacity |

100 mtrs per 8 hrs |

Versatile Rope Braiding Solutions

This machine excels in producing both round and flat braids, accommodating rope diameters from 2 mm up to 12 mm. Its adaptable spindle RPM and horn gear speed ensure precision, while the control panel allows easy adjustment to meet diverse production demands. Suitable for manufacturers working with a variety of synthetic and natural fibers, it satisfies a broad range of industrial and commercial applications.

User-Friendly Operation and Safety

Requiring only one operator, the machine features a simple interface and comprehensive protection against overloads and short circuits. Convenient wheels support easy relocation, and centralized lubrication reduces routine maintenance. Safety and worker comfort are further enhanced by a noise level below 75 dB, making it suitable for extended daily use.

Reliable Performance and Sturdy Construction

Constructed from durable mild steel, this heavy-duty machine ensures stable operation even at high speeds (up to 1,200 RPM). The centralized oil bath system minimizes wear and tear on moving parts, while the V-belt drive guarantees transmission reliability. Each unit is supplied in a secure wooden box for safe shipping and installation.

FAQs of 12 Spindle Rope Braiding Machine:

Q: How does the 12 Spindle Rope Braiding Machine operate?

A: The machine uses a V-belt drive system to rotate 12 spindles, allowing for precise and consistent braiding of ropes. Operations are managed through the control panel, and the horn gear speed is adjustable for different braid styles and rope thicknesses. Only one operator is required to run the machine.Q: What materials can be processed, and what is the typical output?

A: This machine can braid ropes and cords from polypropylene (PP), nylon, polyester, and cotton. It is capable of producing up to 50 meters of braided material per hour, with customizable settings for rope sizes between 2 mm and 12 mm in diameter.Q: When is maintenance required and how is it performed?

A: Routine maintenance is minimized due to the centralized lubrication and oil bath system, which automatically delivers oil to crucial parts. Operators should periodically check oil levels and inspect the system as recommended in the user manual for optimal performance.Q: Where can the machine be installed, and what are the ambient conditions?

A: The machine is suitable for installation in industrial workshops or rope manufacturing facilities. It is designed to operate efficiently in ambient temperatures up to 45C and should be placed on a stable surface; wheels are included for easy repositioning if needed.Q: What is the setup and packaging process for this braiding machine?

A: Each machine is shipped in a durable wooden box to ensure safe transport. Upon arrival, users can position the machine using the attached wheels and follow the supplied setup instructions for quick installation and commissioning.Q: How does the centralized lubrication system benefit users?

A: The centralized lubrication system ensures all key moving components receive consistent lubrication, reducing wear and maintenance frequency. This results in smoother operation, longer machine life, and lower upkeep costs for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

12 Spindle Braiding Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Motor Power : 1.5 kW

Type : Other, Vertical Braiding Machine

Feature : Other, Low noise operation, Sturdy design

Textile Braiding Machine

Price 14000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Motor Power : 23 HP

Type : Other, Vertical Braiding Machine

Feature : Other, Low noise, easy maintenance, high efficiency

Special Braiding Machines

Price 8000-80000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Motor Power : 1.5 kW 3.7 kW

Type : Other, Heavyduty automatic braiding machine

Feature : Other, High speed, low noise, uniform tightness, sturdy design

16 Spindle Braiding Machine

Price 100.00 - 5000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Other, No (Manual/Digital control)

Motor Power : 2 HP

Type : Other, Vertical

Feature : Other, High precision, Low vibration, Energyefficient

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free