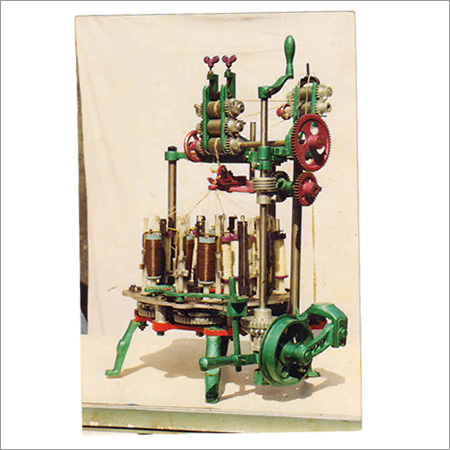

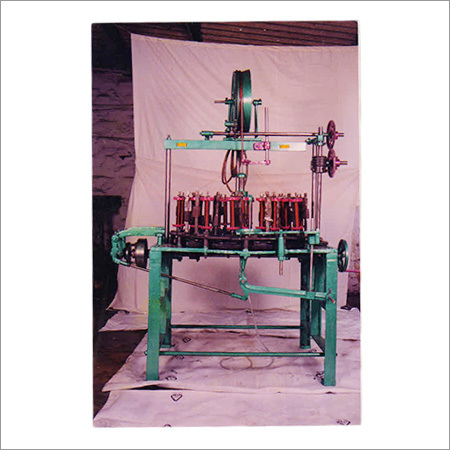

16 Spindle Braiding Machine

Price 5000 INR/ Unit

16 Spindle Braiding Machine Specification

- Machine Speed

- Variable; up to 20 m/min mm/m

- Bobbin Size

- Standard: 38 mm x 120 mm

- Carrier

- 16 carrier system

- Product Type

- 16 Spindle Braiding Machine

- General Use

- Braiding various threads, ropes, cords

- Material

- Heavy-duty steel body

- Capacity

- High output; up to 20 meters/hour depending on material m3/hr

- Weight (kg)

- Approx. 700 kg Kilograms (kg)

- Type

- Vertical

- Machine Power

- 2.2 kW Kilowatt (kW)

- Motor Power

- 2 HP Horsepower (HP)

- Spindle RPM

- 200-1200 RPM RPM

- Traction RPM

- Adjustable up to 300 RPM

- Voltage

- 220-240V / 50-60Hz Volt (v)

- Dimension (L*W*H)

- 1350 mm x 1100 mm x 1850 mm Millimeter (mm)

- Feature

- High precision, Low vibration, Energy-efficient

- Color

- Industrial Green

- Production Counter

- Digital thread meter counter

- Compatible Materials

- Cotton, Polyester, Nylon, PP, and mixed fibers

- Control System

- PLC-based control for precise operation

- Noise Level

- Low-noise design

- Display

- LED operation status display

- Installation Area Required

- Minimum 12 sq. meter

- Safety Features

- Emergency stop and overload protection

- Accessories Included

- Tool kit, spare bobbins, operation manual

- Braiding Diameter Range

- 2 mm to 12 mm

- Maximum Bobbin Capacity

- Up to 16 bobbins

- Lubrication

- Automatic centralized lubrication

- Power Supply Phase

- Single or Three Phase

16 Spindle Braiding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About 16 Spindle Braiding Machine

These 16 Spindle Braiding Machine are made by using very high quality raw material which ensures hassle free work performance at its user end. These are available at a very reasonable price, and are durable and made up of rust resistant steel. These 16 Spindle Double Head Braiding Machine are widely finds its valuable application in various industrial sectors. They require low power consumption and is delivered to the customers after re-checking and on time.

Specification

|

Power Consumption |

0.75 KW |

|

Machine Type |

Automatic |

|

Model Name/Number |

90 Series 16/4 |

|

Brand |

Semco |

|

Speed |

370 RPM |

|

Dimension |

1000 x 1000 x 2000 mm ( L x W x H ) |

|

Production Capacity |

900 meter In 8 Hours |

|

Usage/Application |

Rope, Lace, Fishing, Sports, Textile, Hoisery Etc |

|

Country of Origin |

Made in India |

|

Surface Finishing |

Color Coated |

Advanced Precision and Control

Equipped with a PLC-based control system, the 16 Spindle Braiding Machine ensures exact thread management and minimal errors during operation. The digital control panel, LED status indicators, and digital production counter provide real-time data and enhanced usability, perfectly balancing manual skill with digital convenience for efficient production.

Optimized for Safety and Maintenance

Engineered with an emergency stop and overload protection, this braiding machine delivers a high degree of operational safety. The automatic centralized lubrication and enclosed oil bath system simplify regular maintenance, extend equipment life, and guarantee consistent machine performance with minimal downtime.

Versatile Applications and Materials

Constructed from industrial-grade steel, the machine supports a wide range of materialscotton, polyester, nylon, PP, and fiber blends. Its flexible design allows the production of various cords, ropes, and threads, making it an ideal addition for textile manufacturers, suppliers, and exporters needing reliable, adaptable output with high precision.

FAQs of 16 Spindle Braiding Machine:

Q: How do I operate the 16 Spindle Braiding Machine safely and efficiently?

A: To operate the machine safely, ensure you follow the procedures outlined in the manual, use the emergency stop button in urgent situations, and regularly monitor the LED status display for alerts. The PLC-based digital panel makes operation intuitive, while automatic lubrication keeps moving parts in optimal condition.Q: What materials can be braided with this machine?

A: This machine is compatible with cotton, polyester, nylon, polypropylene (PP), and mixed fiber threads. Its versatility allows you to produce a variety of cords and braids to meet different industry specifications.Q: When should I perform maintenance on the machine?

A: Thanks to automatic centralized lubrication and an enclosed oil bath for spindles, routine maintenance is reduced. However, periodic checks as recommended in the operation manual help ensure long-term reliability and prevent unplanned downtime.Q: Where can the 16 Spindle Braiding Machine be installed?

A: The machine requires a minimum installation area of 12 square meters with either a single or three-phase power supply (220-240V/50-60Hz). Its designed for industrial settings such as textile manufacturing plants.Q: What is the typical production capacity and speed of the machine?

A: Depending on the material, the machine can output up to 20 meters per hour and operate at spindle speeds ranging from 200 to 1200 RPM and variable traction speed up to 300 RPM, allowing flexibility for different product requirements.Q: What are the key benefits of using this braiding machine?

A: Key benefits include high-precision braiding, low vibration and noise, energy efficiency, adjustable speed and horn gear, and compatibility with both semi-automatic and fully automatic operations. Accessories like spare bobbins and a tool kit further enhance convenience and productivity.Q: How does the machine measure production and monitor operation status?

A: A digital thread meter counter tracks output precisely, while the LED display provides continuous updates on machine status, making it easy for operators to oversee production and address issues promptly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Braiding Machines Category

17 Spindle Braiding Machine

Price 5400 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue & White

Feature : Other, High Performance, Robust Construction

Bobbin Size : 120 mm x 36 mm

Material : Other, Mild Steel Body

Special Braiding Machines

Price 8000-80000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Green/Blue or as per order

Feature : Other, High speed, low noise, uniform tightness, sturdy design

Bobbin Size : Standard: 48 mm; other sizes on request

Material : Other, Highgrade steel, cast iron

Textile Braiding Machine

Price 14000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : Sky Blue

Feature : Other, Low noise, easy maintenance, high efficiency

Bobbin Size : Standard (Customizable as per requirement)

Material : Other, Mild Steel Body

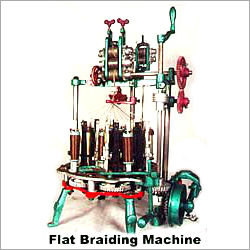

Flat Braiding Machine

Minimum Order Quantity : 1 Unit

Color : Industrial Blue & Silver

Feature : Other, Low Noise, Smooth Operation, Compact Design

Bobbin Size : 48 mm x 140 mm

Material : Other, Mild Steel (Frame and Parts)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free